vickers hardness test experiment|vickers microhardness test procedure : member club The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees . How to Get *NEW* PIXEL NINJA SKIN for FREE in Stumble Guys#stumbleguys @upyoddhaawebsite link 🔗 https://store.stumbleguys.com/Follow Me On Instagram :- htt.

{plog:ftitle_list}

webResultados do Euromilhões. Os últimos resultados do Euromilhões são publicados aqui imediatamente após o sorteio. Poderá consultar a chave do sorteio, bem como a distribuição de prémios, os premiados e resultados do M1lhão. A chave vencedora é mostrada abaixo, juntamente com o código do M1lhão para cada sorteio de sexta-feira.

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .

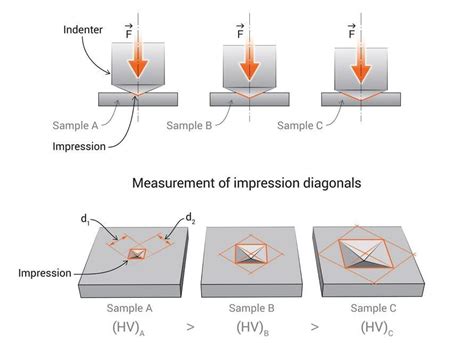

Experiment No. 2 VICKERS HARDNESS TEST Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and .The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees .

Static indentation tests are one way to determine hardness. For static indentation, a cone, pyramid, or ball is forced into the surface of the material. .The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low .

Vickers hardness test requires a diamond pyramid indenter with an included angle of 136o. This technique is also called a diamond pyramid hardness test (DPH) according to the shape of the .Vickers hardness testing has been widely used as one of the basic and reliable material test methods. Furthermore, triangular pyramidal indentation technique (the nanoindentation .Vickers Hardness Test. The Vickers hardness test was developed by RL. Smith and Sandland in 1921 at Vickers Ltd as an alternative to brinell hardness test method to measure the hardness of the material.Learn all you need to know about Vickers microhardness testing and microhardness testing machines – with knowledge, insight and troubleshooting tips from Struers, one of the world’s leading Vickers micro hardness tester .

Basic principle and practical procedure of the Vickers hardness test - Testing machine, test piece, diamond pyramid indenter - Basic principle, hardness de.

Experiment on Vickers hardness test. Group 10 Samuel Olakanmi (202202443) Atlarelang Mhateng (202206923) Golebaone Motsumi (202206035) Katlo Morwamang(20200402) Ame Seamolo(202304327) Abstract Mechanical .The Brinell test for this experiment uses steel ball with different diameters which is pressed into a specimen by a different load that is maintained for 15 to 30 seconds. . The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 .Explore the Vickers Hardness Test, its methodology, and applications in material science. Detailed guide available at Infinita Lab. . Tensile Test Experiment . ASTM E8M Tension Testing of Metallic Materials . Case Study In-depth examination of genuine material testing solutions. Dopant and ultra-low concentration elemental analysis using .

Experiment Six (6) Hardness Testing Introduction Objective: . Vickers hardness test requires a diamond pyramid indenter with an included angle of 136o. This technique is also called a diamond pyramid hardness test (DPH) according to the shape of the indenter. To carry on the test, the diamond indenter is pressed on to a prepared metal surface .

The Vickers hardness test was developed by RL. Smith and Sandland in 1921 at Vickers Ltd as an alternative to brinell hardness test method to measure the hardness of the material. The Vickers hardness test follows the brinell principle, in that an indenter of definite shape is pressed into the material to be tested, then the load is removed and . Hardness testing is an essential test in the metal manufacturing industry, and Vickers hardness is one of the most widely used hardness measurements today. The computer-assisted Vickers hardness test requires manually generating indentations for measurement, but the process is tedious and the measured results may depend on the operator’s experience. In .15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were performed on the cross-section surfaces of the rolled strips along the .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

The Vickers method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6507, ASTM E92, ASTM E384).VICKERS HARDNESS TEST: The Vickers hardness test uses a square base diamond pyramid as the indenter. The included angle between the opposite faces of the pyramid is l36°. The Vickers hardness tester operates on the same basic principle as the Brinell tester, the numbers being expressed in the terms of load and area of the impression. In the experiment al work that has been carried out, in the case of the Vickers hard ness testing. . Vickers hardness testing is one of the most useful methods to determine the hardness of .

limitations of rockwell hardness testing

Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding Loads. Method Load Range Standard; Method. Brinell. Load Range. 1 kgf–3,000 kgf. Standard. ASTM E10, ISO 6506. Method.The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure t. The advantages of the Vickers hardness test is the extremely accurate readings can be taken and just one type of indenter is used for all types of metals. The Vickers test is capable of testing soft and hard material. The .PRACTICAL HARDNESS TESTING MADE SIMPLE Table of Contents Page 1. GENERAL 1 2. INTRODUCTION 3 3. BRINELL HARDNESS TESTING 9 4. VICKERS HARDNESS TESTING 14 5. ROCKWELL HARDNESS TESTING .

Experiment Five- Principals of Stress and Strains Test Experiment Six (6) Hardness Testing . the yield strength at 0.2% offset can be determined from the Vickers hardness number as shown in the . We calculated the Vickers hardness (\(H_v\)) using the six relations and compared the results with the experiment to evaluate which method is more suitable for each material kind. We observed the .A square base pyramid shaped diamond is used for testing in the Vickers scale. Typically loads are very light, range from 10gm to 1kgf, although “Macro” Vickers loads can range up to 30 kg or more. 1 Objectives 2. Understand the preparation procedure of Vickers hardness testing. 3. Understand the concept of Vickers hardness testing. 4.

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. . For Vickers experiment, student has to calculate the VHN through the following formula for each material .The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test. + 86 755 61301520; [email protected]; Search.This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers hardness test.. The Vickers hardness scale, named after the company where it was developed in 1921, is the focus of this article.

The Vickers hardness test is based on the principle of indentation hardness, where a diamond indenter with a square-based pyramid shape is pressed into the surface of the material under a specified load. The diagonals of the resulting indentation are measured using a microscope, and the Vickers hardness value is calculated using a formula that .The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the surfaceVickers is a hardness test for all solid materials, including metallic materials. The Vickers Hardness (HV) is calculated by measuring the diagonal lengths of an indent in the sample material left by introducing a diamond pyramid indenter with a given load. The diagonals of the indent are measured optically in order to determine the hardness .Vickers Hardness Test; In Vickers test, it involves a diamond indenter in the form of a square-based pyramid with an apex angle of 136 ̊. The indenter is being pressed under load for 10 to 15 seconds into the surface of the specimen under test. The result is a square-shape indentation. After the load and indenter are removed the diagonals of .

The Vickers hardness test is similar to the Brinell test. However, it uses a four-sided inverted diamond pyramid with an apex angle of 136°. The Vickers hardness number (HV) is the ratio of the impressed load to the square indented area. The Vickers hardness test is of particular value for hard, thin materials where hardness at a spot is required.

vickers microhardness test procedure

webThicc Goth Trans Girl Stephanie Erin, Massive Cumshot. 3:56:30. 95 %. Peachy Lily - peachy.lily - Compilation. Peachy Lily - peachy.lily - Compilation. 720p 19:32. 100 %. Cute Danni cums some on friends face at 17:42. Cute Danni cums some on friends face at 17:42.

vickers hardness test experiment|vickers microhardness test procedure